The Juice Sterilization Production Line is an advanced, high-efficiency solution for producing safe, high-quality juices. Designed to meet stringent food safety standards, this line provides precise sterilization and pasteurization techniques that preserve the natural taste, color, and nutrients in a variety of juice products. With automated processing, optimized heat distribution, and tailored settings for various juice densities, from bottles to cartons, ensuring long shelf life without compromising product quality.

Juice Sterilization Production Line

Working Process

The workflow of the juice sterilization production line is simple and efficient. Freshly extracted juice undergoes initial filtering and optional blending, then pre-heating to reduce microbial load before container filling. The filled containers are sterilized in selected kettles, such as water bath or side-spraying models, which ensure consistent, even heat. Once sterilized, the juice is quickly cooled, dried, labeled, and packaged for extended freshness and stability.

Key Machines

-

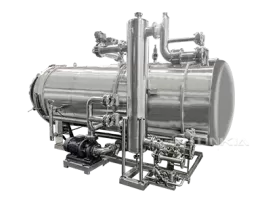

1Packing Bottle Water Spray Retort

The packing bottle water spray retort provides precise, high-temperature sterilization through top spraying and water bath immersion, maintaining the juice's quality while effectively eliminating microbial threats. The dual-purpose electric and steam design enhances adaptability, allowing you to choose the heating mode based on needs, thereby reducing energy consumption.

-

2Steam Water Spray Retort

The combination of water bath and full shower sterilizer adopts comprehensive spraying technology, which can carry out all-round heat treatment to the products during the sterilization process and ensure that the juice in each package is subjected to uniform sterilization, which is suitable for a variety of packaging forms of fruit juice products.

-

3Side Spraying Water Spray Retort

Side spraying water spray retort features targeted spraying for consistent thermal treatment, particularly useful for juices in various packaging forms, such as bottles, cans, and cartons.

Applications

Fruit Juices (e.g., orange, apple, and mixed berry)

Vegetable Juices (e.g., carrot, celery)

Herbal and Functional Drinks (e.g., aloe vera, ginger-infused drinks)

Blended Beverages

Prev Article: Vacuum Corn Packing Production Line

Next Article: Amazing Canned Food Sterilization Production Line