The Concentrated Bone Broth Production Line is a specialized solution engineered to produce nutrient-rich bone broth with consistent texture and deep flavor. This production line is optimized for extracting maximum nutrients, collagen, and minerals from bones, offering a robust and reliable process suitable for a variety of production needs, from small batches to large-scale operations. Designed to streamline every step, this line emphasizes efficiency, hygiene, and optimal extraction techniques that reduce oxidation and retain the broth’s natural goodness.

Concentrated Bone Broth Production Line

Working Process

The working process of the Concentrated Bone Broth Production Line begins with the roasting or sautéing of bones and aromatics in the planetary stirring jacketed kettle, enhancing flavor through caramelization. The roasted ingredients are then transferred to the industrial reaction kettle, where they are simmered under controlled low temperatures to extract maximum nutrients and collagen. The broth is concentrated in the horizontal vacuum cooker mixer, which ensures uniform consistency and further reduces oxygen exposure. Finally, the broth is filtered, packaged, and sterilized, ensuring a clear, nutrient-rich product ready for distribution.

Key Machines

-

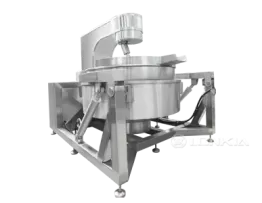

1Fully Automatic Planetary Stirring Jacketed Kettle

Planetary stirring jacketed kettle is one of the key equipment in the concentrated bone broth production line, which is mainly used for bone simmering and preliminary heating of broth materials. Its unique planetary stirring function ensures even heating and stirring of the materials in the pot, which is ideal for frying or pre-roasting bones to enhance the flavor of the broth.

-

2Industrial Reaction Kettle

The industrial reaction kettle is ideal for extracting nutrients like gelatin and collagen from bones, making it essential for concentrated bone broth production line. Made of stainless steel, it resists high temperatures and corrosion and is easy to clean. Its sealed design ensures broth quality by preventing contamination.

-

3Horizontal Vacuum Cooker Mixer

The vacuum feature of horizontal vacuum cooker mixer assists in concentrating the broth further while its horizontal axis stirring ensures minimal sedimentation, resulting in a high-quality, uniform product with a rich mouthfeel.

Applications

Bone Broth Concentrates: Suitable for consumers seeking a nutritious, convenient base for soups, stews, or standalone consumption.

Soup Bases and Stock Concentrates: The concentrated broth production line is popular in food service industries, adding rich flavor to a range of dishes.

Health and Wellness Products: Used in health-focused brands for collagen supplements, protein-rich broths, and ready-to-drink wellness beverages.

Prev Article: Fully Automatic Popcorn Production Line

Next Article: Professional Congee Production Line