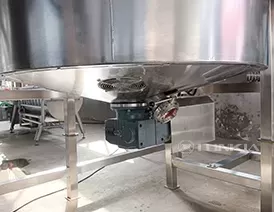

The industrial reaction kettle is a critical piece of equipment designed to facilitate and control chemical reactions across multiple industries, including food processing and materials engineering. This advanced system allows for precise mixing and temperature regulation, ensuring optimal conditions for various reactions. By integrating state-of-the-art technology, the Reaction Kettle enhances the efficiency and consistency of product formulations, while also ensuring safety and compliance with industry standards.