The Canned Food Sterilization Production Line is designed to deliver high-quality sterilization for a wide range of canned products, including vegetables, meats, soups, and ready-to-eat meals. By applying controlled heat and pressure, this line ensures food safety and a long shelf life without compromising the texture, flavor, or nutritional value. The automated process accommodates large production volumes while maintaining consistent quality.

Canned Sterilization Production Line

Key Machines

-

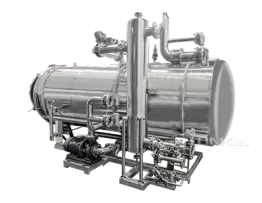

1Industrial Water Spray Retort

The industrial water spray retort ensures uniform heat penetration for delicate canned items through both water immersion and spraying, suitable for products that require gentle handling.

-

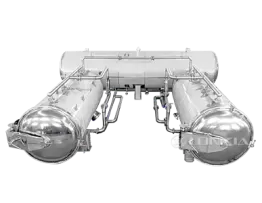

2Rotary Water Spray Retort

The rotary water spray retort adds a rotating function on the basis of water bath sterilizing, so that the cans are constantly rotating during the sterilizing process. This ensures uniform processing of the contents and reduces the settling of sticky products.

-

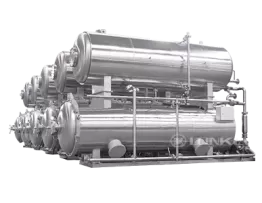

3Side Spraying Sterilization Kettle

The water spray retort provides customizable side-spraying techniques to precisely target heat for specific can sizes and shapes, minimizing energy consumption.

-

4Rotary Retort Autoclave

The rotary retort autoclave can improve heat distribution and processing efficiency through high-speed rotation, effectively preventing food from settling and achieving uniform sterilization at the same time. This equipment is especially suitable for a variety of specifications and shapes of canned products.

Applications

Canned vegetables: such as peas, carrots and green beans

Canned meat: such as chicken, beef and pork

Canned soups and stews: ready-to-eat foods that require an extended shelf life

Canned fruit preserves: fruit canned in syrup or juice

Canned legumes: beans, lentils and chickpeas

Canned seafood: canned tuna, salmon and sardines

Prev Article: Best Juice Sterilization Production Line

Next Article: Sausage Sterilization Production Line With Good Performance