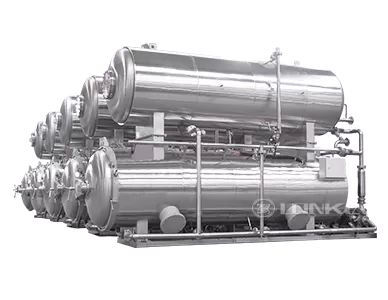

The bottle retort autoclave is a high-efficiency, advanced sterilization system designed to handle large volumes of products while maintaining optimal sterilization conditions. The key feature of this machine is its cage rotation mechanism, which ensures uniform heat distribution and minimizes product damage during the sterilization process. Operating at a rotation speed of 1400 RPM, this system is specifically engineered for canned goods, jars, and bottled products that require gentle yet thorough sterilization to extend shelf life and ensure food safety.