The Sausage Sterilization Production Line is designed to ensure food safety, quality, and extended shelf life for various sausage products, including smoked, cooked, and raw sausages. By using precise heat and pressure control, the line guarantees effective sterilization without compromising the texture, flavor, or appearance of the sausages. This automated system allows for high production throughput and minimal human intervention, making it suitable for large-scale food processing facilities focused on efficiency and consistent quality.

Sausage Sterilization Production Line

Working Process

The sausage sterilization production line begins with automated loading of packaged sausages into the selected sterilization kettles. Sausages undergo a water bath or steam-based sterilization process at controlled temperatures and pressures. Depending on product requirements, rotary or side-spraying options are used to ensure uniform heat penetration. After sterilization, sausages are quickly cooled to lock in quality, and then dried for packaging. The system’s precise controls allow for customized sterilization cycles to suit various sausage types and packaging formats.

Key Machines

-

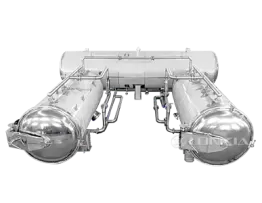

1Rotary Water Spray Retort Machine

The rotary water spray retort machine is ideal for sausages, as it allows for gentle rotation during sterilization to prevent product deformation while ensuring even heat distribution.

-

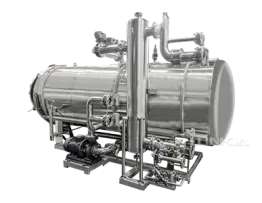

2Side Spraying Sterilization Kettle

The side spray sterilization kettle ensures rapid and uniform temperature changes by evenly spraying the heating or cooling medium over the product surface. It flexibly adjusts spray intensity and temperature, making it ideal for sterilizing sausages in various packaging forms.

-

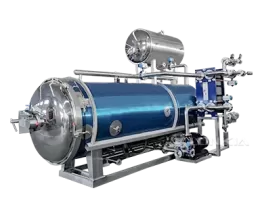

3Top Spraying and Side Spraying Sterilization Kettle

The retort machine combines the functions of top shower and side spray, thoroughly covering the spraying range and further improving the sterilization efficiency. It is suitable for uniform and fast sterilization of sausages in different packages. You can contact us anytime to get the energy efficient autoclave sterilization.

Applications

Cooked Sausages: such as hot dogs and bologna

Smoked Sausages: like bratwurst and kielbasa

Raw Sausages: including fresh Italian sausage and chorizo

Cured and Dried Sausages: such as salami and pepperoni (for specific processing needs)

Prev Article: Amazing Canned Food Sterilization Production Line

Next Article: Nuts Roasting Frying Production Line