Maintaining Consistent Food Quality with Water Spray Retorts: Tips and Best Practices

In the food processing industry, maintaining consistent quality and safety is crucial, especially when using water spray retorts for sterilization. These systems ensure that food products are free from harmful microorganisms while preserving their taste, texture, and nutritional value. However, to achieve optimal results, manufacturers must follow best practices to prevent inconsistencies in sterilization.Below are some essential tips and best practices for maintaining high-quality food production with…

Learn MoreCommon Challenges in Water Spray Retort Sterilization and How to Overcome Them

Water spray retort sterilization is a widely used method in the food and beverage industry, ensuring that products achieve commercial sterility while maintaining quality and extending shelf life. However, like any industrial process, it comes with its own set of challenges. Understanding these issues and their solutions is key to achieving efficient, safe, and consistent sterilization.1. Uneven Heat Distribution🔍 The Challenge:One of the most common issues in water spray retort systems is inconsistent heat…

Learn MoreUnderstanding the Working Principle of Water Spray Retorts in Food Manufacturing

In food manufacturing, sterilization is essential to ensure product safety, extend shelf life, and meet regulatory standards. Among the various sterilization technologies, water spray retorts have become a preferred choice due to their efficiency, uniform heat distribution, and energy-saving capabilities. But how do they work, and why are they beneficial for food processors?In this blog, we will explore the working principle of water spray retorts, their key components, and their advantages in food…

Learn MoreEnergy Efficiency in Food Processing: The Role of Water Spray Retorts

Energy efficiency is a key concern for modern food processing facilities, where high energy consumption not only increases operational costs but also impacts environmental sustainability. Among various sterilization technologies, water spray retorts have emerged as an effective solution for reducing energy use while maintaining product safety and quality.In this blog, we explore how water spray retorts contribute to energy-efficient food processing and why they are a smart investment for manufacturers.1.…

Learn MoreHow a Water Spray Retort Can Improve the Shelf Life of Your Food Products

In the food industry, preserving product quality and extending shelf life are critical factors for maintaining both safety and customer satisfaction. One of the most effective methods to achieve this is through the use of water spray retorts. At LONKIA Machinery, we specialize in providing high-performance water spray retorts designed to help businesses improve their food preservation processes. Let’s explore how a water spray retort can significantly enhance the shelf life of your food products.1. Optimal…

Learn MoreKey Features to Look for in a High-Performance Water Spray Retort

When choosing a water spray retort for your industrial needs, the focus should be on both efficiency and reliability. LONKIA Machinery understands the critical role these systems play in preserving product quality and enhancing operational productivity. Here are the key features to consider when selecting the right water spray retort for your facility.1. Precision Temperature ControlThe temperature regulation of a water spray retort is crucial to ensure consistent processing. A high-performance system…

Learn MoreWater Spray Retort vs. Traditional Retort Systems: Which Is Better for Your Business?

When it comes to food processing and sterilization, retort systems are a critical component for ensuring food safety and shelf life. In recent years, water spray retorts have emerged as a popular alternative to traditional retort systems. But how do they compare? Which one is better for your business? Let’s dive into the key differences, benefits, and potential drawbacks of each to help you decide which system best suits your operations.What is a Retort System?A retort is a pressure cooker used in food…

Learn MoreWhy Water Spray Retort Machines Are Essential for Ready-to-Eat Meal Production

Ready-to-eat (RTE) meals have become increasingly popular due to their convenience, long shelf life, and ability to retain flavor and nutrition. However, ensuring food safety and quality in RTE meal production requires advanced sterilization methods. One of the most effective solutions is the Water Spray Retort Machine. This article explores why water spray retort machines are essential for RTE meal production and how they contribute to food safety, efficiency, and product quality.1. Ensuring Food Safety…

Learn MoreThe Benefits of Using a Water Spray Retort for Canned Foods

The Water Spray Retort is a highly effective sterilization method commonly used in the canned food industry. By using a combination of pressurized hot water spray and steam, this system ensures that canned foods are safely sterilized while preserving their quality. Below, we highlight the key benefits of using a Water Spray Retort for canned foods.1. Uniform SterilizationOne of the main advantages of a Water Spray Retort is its ability to provide consistent heat distribution. The pressurized water and…

Learn MoreHow Does a Water Spray Retort Enhance Food Sterilization?

The Water Spray Retort is an advanced sterilization system used in the food industry to ensure food safety, prolong shelf life, and maintain product quality. This method uses a combination of pressurized hot water spray and steam to sterilize food inside sealed containers. Below, we explore how a Water Spray Retort enhances food sterilization and its key advantages.1. Consistent and Even Heat DistributionOne of the main benefits of a Water Spray Retort is its ability to provide uniform heat distribution…

Learn MoreJuice Sterilization Production Line

The Juice Sterilization Production Line is an advanced, high-efficiency solution for producing safe, high-quality juices. Designed to meet stringent food safety standards, this line provides precise sterilization and pasteurization techniques that preserve the natural taste, color, and nutrients in a variety of juice products. With automated processing, optimized heat distribution, and tailored settings for various juice densities, from bottles to cartons, ensuring long shelf life without compromising…

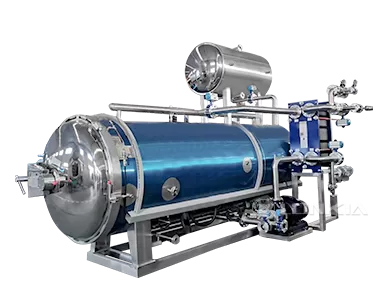

Learn MoreJar/Bottle/Can Water Spray Retort

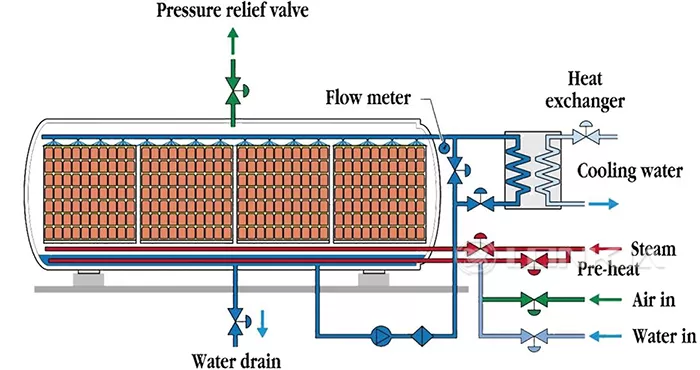

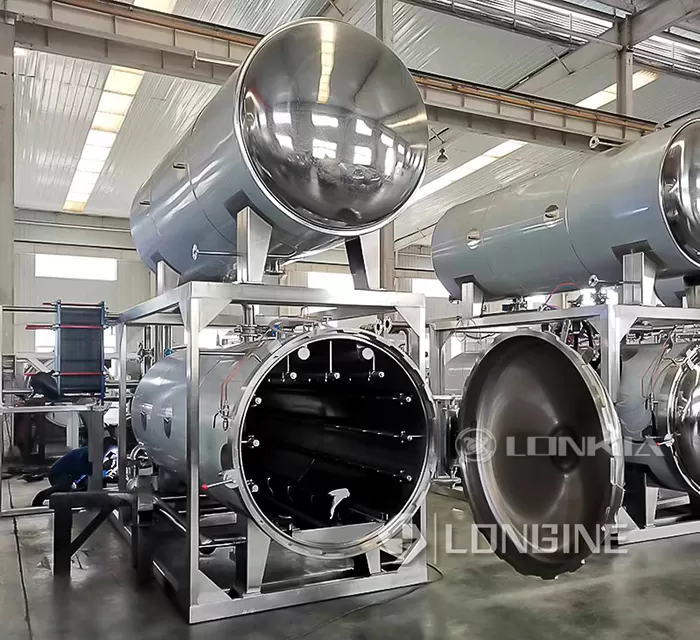

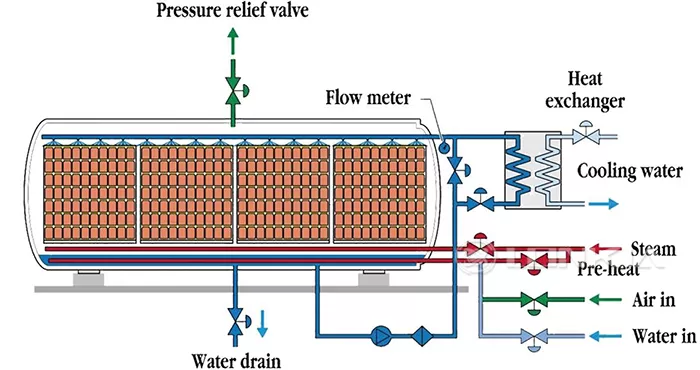

The jar/bottle/can water spray retort is a highly efficient sterilization equipment designed for modern food processing. The sterilization kettle utilizes side-mounted spray nozzles to provide 360-degree coverage, offering uniform heat distribution and ensuring even temperature control during the sterilization cycle. This design allows the kettle to handle a variety of food products, including those with complex or irregular packaging. Whether sterilizing canned goods, pouches, bottles, or glass jars, the…

Learn MorePacking Bag/Bottle Retort Machine

The packing bag/bottle retort machine offers an advanced, multi-directional sterilization process designed to meet the specific needs of food products with varying viscosities and packaging types. By utilizing both top and side spraying mechanisms, it ensures uniform heat distribution across a wide range of containers, including cans, bottles, and pouches, thereby achieving optimal sterilization without compromising product integrity.

Learn MorePacking Bag/Jar Steam Water Spray Retort

The packing bag/jar steam water spray retort is engineered for high-efficiency sterilization of various food products, ensuring optimal safety and quality. This advanced equipment combines a water bath system with a full spraying mechanism to provide uniform heat distribution and thorough sterilization. The design enables direct immersion of the product, which maintains its integrity and improves sterilizing effect while enhancing production efficiency, making it an important and indispensable piece of…

Learn MorePacking Bag Water Spray Retort

The packing bag water spray retort is designed for efficient and versatile sterilization processes. This innovative equipment features a dual-use system that can operate using both electric and steam heating methods, providing flexibility for various production environments. The double-layer design ensures even heat distribution while maximizing energy efficiency. The top spraying mechanism enhances sterilization effectiveness by uniformly distributing hot water or steam over the products, ensuring…

Learn More