The vacuum corn packing production line is designed to process fresh corn while preserving its natural flavor, nutritional value, and texture using advanced vacuum packaging techniques. This line is equipped with state-of-the-art machines to handle every step of the process from cleaning and blanching to sterilization, cooling, and vacuum sealing. By eliminating air exposure, the vacuum-packed system ensures an extended shelf life without compromising the quality of the corn.

Vacuum Corn Packing Production Line

Working Process

The working process for the vacuum corn packing production line begins with peeling and cleaning the fresh corn to remove husks and silk. The corn is then blanched to preserve its flavor, color, and nutrients, followed by a sterilization step in the water spray retort machine to ensure safety and extended shelf life. After sterilization, the corn is quickly cooled to maintain its texture and flavor, then vacuum-sealed to eliminate air and prevent spoilage.

Key Machines

-

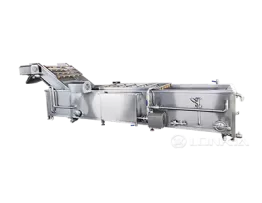

1Corn Peeling and Washing Machine

The corn peeling and washing machine is the first in the vacuum corn packing production line, efficiently removing husks, silks, and debris from fresh corn. Made of durable stainless steel for food hygiene compliance, it ensures clean kernels and adjusts to various corn sizes and shapes for high-quality output.

-

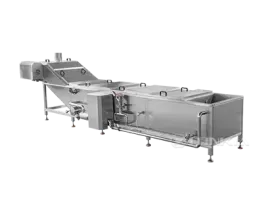

2Corn Blanching Machine

Corn blanching machine is an indispensable equipment for vacuum corn packing production line, used to blanch the corn to preserve color, texture, and nutritional value while deactivating enzymes. Prevents spoilage, enhances the flavor profile, and ensures uniform product quality.

-

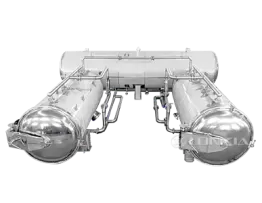

3Water Spray Retort Machine

The water spray retort machine sterilizes the corn by means of a water bath with precise temperature and time control. Effectively eliminates bacteria and pathogens, ensuring the corn is safe for long-term storage, while retaining its original taste and texture.

-

4Vacuum Packaging Machine

Seals the sterilized corn in vacuum bags to eliminate air and protect the product from oxidation and contamination. Extends the shelf life of the product, preserves flavor, and prevents freezer burn in frozen products.

Applications

Vacuum-Sealed Corn on the Cob: Packaged as fresh corn on the cob.

Frozen Vacuum-Sealed Corn: Ideal for frozen food products, extending the shelf life.

Export-Grade Vacuum Corn: Packaged for international markets, ensuring quality and freshness upon arrival.

Retail Packaging: Suitable for supermarket shelves.

Corn for Food Service: Ideal for use in restaurants, caterers, and institutional kitchens.

Prev Article: High Efficiency Zongzi Sterilization Line

Next Article: Best Juice Sterilization Production Line