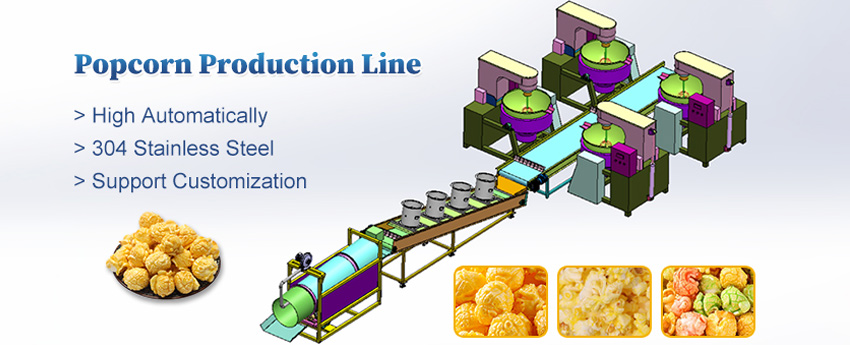

The popcorn production line specializes in processing corn kernels, which are made into crunchy and tasty popcorn of different kinds and crunchy and tasty through a series of process steps. This kind of production line is widely used in food processing industry, especially in snack food processing, movie theaters, shopping malls and other places. Our popcorn production line can realize efficient, hygienic and automated production to meet the demand of mass production. Next, we will introduce the popcorn production line in detail.

Fully Automatic Popcorn Production Line

Working Process

How does the production process of a popcorn production line work? The popcorn production process begins in the planetary stirring jacketed kettle, where corn kernels are heated in hot oil, allowing them to pop while absorbing flavoring. If you want to try different flavors of popcorn, add the appropriate seasonings to the pan. For example, to make Caramel-flavored popcorn, sprinkle powdered Caramel into the pan and toss to coat. The freshly popped popcorn then moves onto the cooling conveyor, where it is cooled to maintain its crisp texture. Finally, the drum sifter sorts out any unpopped kernels, ensuring a high-quality final product ready for packaging.

Key Machines

-

1Planetary Stirring Jacketed Kettle

The planetary stirring jacketed kettle one of the core equipment in popcorn production line, which utilizes hot oil to pop corn kernels and season them simultaneously. Provides uniform heating and efficient flavor incorporation, resulting in perfectly popped corn with rich taste.

-

2Cooling Conveyor

Cooling conveyor is used to cool the freshly popped popcorn to preserve its crunchiness. Prevents moisture retention, ensuring that the final product remains light and crispy.

-

3Drum Sifter

Separates unpopped kernels from fully popped popcorn. Enhances product quality by ensuring that only the best popcorn reaches packaging, minimizing waste.

Applications

Butter Popcorn,Cheddar Cheese Popcorn,Caramel Popcorn,Sea Salt Popcorn,Chocolate Popcorn, Spicy Popcorn,Strawberry Popcorn.

Next Article: Concentrated Bone Broth Production Line