Ready-to-eat (RTE) meals have become increasingly popular due to their convenience, long shelf life, and ability to retain flavor and nutrition. However, ensuring food safety and quality in RTE meal production requires advanced sterilization methods. One of the most effective solutions is the Water Spray Retort Machine. This article explores why water spray retort machines are essential for RTE meal production and how they contribute to food safety, efficiency, and product quality.

1. Ensuring Food Safety and Extended Shelf Life

One of the biggest challenges in RTE meal production is eliminating harmful bacteria and pathogens while preserving the taste and texture of the food. Water spray retort machines achieve this by using:

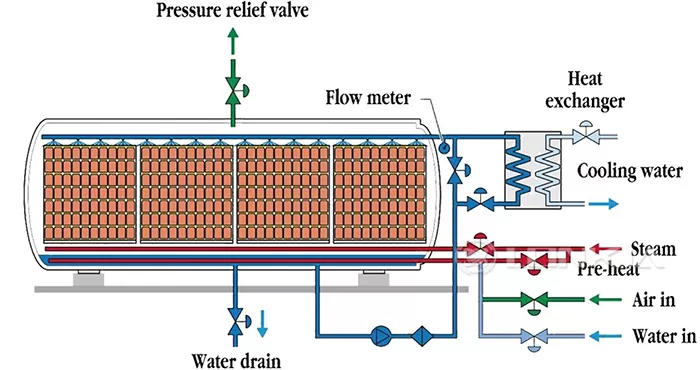

✔ Pressurized hot water spray to evenly distribute heat across packaged meals, ensuring thorough sterilization.

✔ Precise temperature and pressure control to meet food safety regulations.

✔ Uniform heat penetration even for dense or high-protein meals, reducing the risk of under-processing.

By using a water spray retort machine, food manufacturers can extend the shelf life of their products without relying on excessive preservatives, making them healthier and safer for consumers.

2. Maintaining Product Quality and Nutritional Value

Unlike traditional sterilization methods, water spray retort machines are designed to minimize thermal damage to food while ensuring effective microbial elimination. This is particularly important for RTE meals, where maintaining texture, flavor, and nutrients is key to customer satisfaction.

🔹 Gentle Processing: The controlled heating and cooling process reduces the risk of overcooking or nutrient loss.

🔹 Prevents Package Distortion: The gradual temperature changes prevent deformation of flexible pouches, trays, or cans.

🔹 Consistent Results: Advanced monitoring systems ensure every batch meets the same quality standards.

These advantages make water spray retort machines the preferred choice for preserving soups, curries, meat-based dishes, and plant-based meals without compromising on quality.

3. Improving Production Efficiency and Cost-Effectiveness

For large-scale RTE meal production, efficiency is a critical factor. Water spray retort machines help manufacturers achieve higher productivity and cost savings in several ways:

✅ Faster Processing Time – Water conducts heat more efficiently than steam, reducing sterilization cycles.

✅ Energy and Water Efficiency – Advanced retort systems recycle water and optimize heat distribution, lowering operational costs.

✅ Automation and Monitoring – Modern machines come with programmable logic controllers (PLC), allowing real-time adjustments to ensure process accuracy.

✅ Versatile Packaging Compatibility – Works with metal cans, plastic trays, glass jars, and retort pouches, making it a flexible solution for different RTE meal formats.

By integrating a water spray retort machine into their production line, food manufacturers can increase throughput, reduce waste, and enhance overall profitability.

Conclusion

Water spray retort machines play a vital role in ensuring food safety, maintaining product quality, and optimizing production efficiency in ready-to-eat meal manufacturing. Their ability to provide uniform sterilization, gentle heat treatment, and energy efficiency makes them an essential investment for any food producer looking to deliver safe, high-quality, and long-lasting RTE meals.

For manufacturers aiming to stay competitive in the fast-growing RTE meal market, adopting water spray retort technology is a smart and future-proof decision.