In food manufacturing, sterilization is essential to ensure product safety, extend shelf life, and meet regulatory standards. Among the various sterilization technologies, water spray retorts have become a preferred choice due to their efficiency, uniform heat distribution, and energy-saving capabilities. But how do they work, and why are they beneficial for food processors?

In this blog, we will explore the working principle of water spray retorts, their key components, and their advantages in food manufacturing.

1. What is a Water Spray Retort?

A water spray retort is an advanced sterilization system used to process packaged food products such as canned foods, ready-to-eat meals, dairy products, and beverages. It utilizes high-pressure water sprays to distribute heat evenly around the packaged food, ensuring effective sterilization while minimizing energy and water consumption.

Compared to traditional steam or water immersion retorts, water spray retorts offer:

- Faster and more uniform heat transfer

- Lower water usage due to recirculating spray technology

- Precise temperature control for consistent sterilization

2. How Does a Water Spray Retort Work?

The sterilization process in a water spray retort consists of four key phases:

Step 1: Loading and Sealing

Food products are placed inside sealed containers (cans, pouches, bottles, or jars) and loaded into the retort chamber. The retort door is securely closed to maintain a controlled processing environment.

Step 2: Heating Phase

Water is heated using steam or an external heat exchanger to reach the required sterilization temperature.

High-pressure pumps spray hot water onto the containers from multiple nozzles, ensuring even heat distribution.

The combination of high-velocity water spray and forced convection accelerates the heating process, reducing sterilization time.

Step 3: Holding Phase (Sterilization)

The system maintains a precise temperature (typically between 110°C and 135°C, depending on the product).

The heat effectively kills harmful bacteria, ensuring food safety and extending shelf life.

Overpressure control ensures that flexible packaging (such as pouches or plastic containers) maintains its shape and integrity during processing.

Step 4: Cooling Phase

After sterilization, cooling water is sprayed over the containers to gradually lower their temperature.

The cooling system recirculates and filters water to reduce waste and energy consumption.

Once the temperature reaches a safe level, the retort door is opened, and the sterilized food products are removed for further processing or packaging.

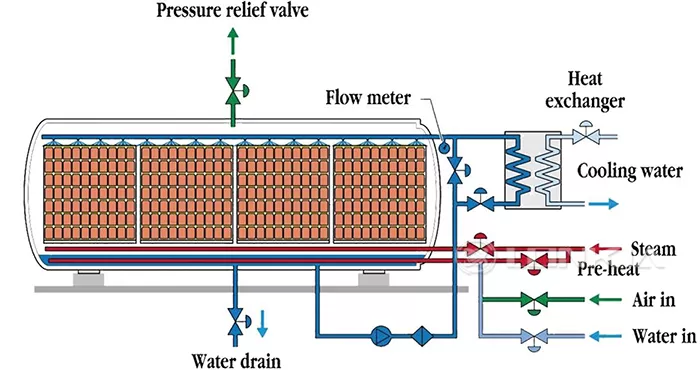

3. Key Components of a Water Spray Retort

A modern water spray retort consists of the following essential components:

- Retort Chamber: The main body where food products undergo sterilization.

- Water Spray Nozzles: Strategically positioned to ensure even heat distribution.

- Heat Exchanger: Transfers heat efficiently without direct steam contact.

- Circulation Pump: Ensures continuous water flow for uniform heating and cooling.

- Temperature & Pressure Control System: Maintains precise processing conditions.

- Cooling & Water Recirculation System: Reduces water usage and improves efficiency.

4. Advantages of Water Spray Retorts in Food Manufacturing

1. Faster and More Uniform Sterilization

The high-pressure spray system ensures even heat distribution, reducing sterilization time and preventing overheating of certain areas.

2. Energy and Water Efficiency

- Lower water consumption due to the recirculating spray system.

- Reduced energy costs through optimized heat transfer and shorter processing times.

- Heat recovery technology can be integrated to further improve efficiency.

3. Suitable for a Wide Range of Packaging

Water spray retorts are ideal for sterilizing:

- Metal cans and glass jars

- Plastic trays and bottles

- Flexible pouches (retort pouches) and cartons

4. Enhanced Product Quality and Shelf Life

- Prevents overcooking or texture loss due to precise temperature control.

- Retains better color, flavor, and nutritional value in processed foods.

5. Reliable and Safe Operation

- Automated control systems ensure consistent processing.

- Overpressure control prevents damage to delicate packaging materials.

- Built-in safety features minimize operational risks.

5. Choosing the Right Water Spray Retort for Your Business

When selecting a water spray retort, consider the following:

- Processing capacity: Choose a model that fits your production scale.

- Automation level: Advanced PLC control systems enhance precision and efficiency.

- Energy-saving features: Look for heat recovery and water recycling systems.

- Material quality: Stainless steel construction ensures durability and easy cleaning.

At LONKIA Machinery, we specialize in high-performance water spray retorts designed for efficient and reliable sterilization in food manufacturing. Our advanced retort systems help businesses improve productivity, reduce costs, and ensure top-quality food safety standards.

Conclusion

Understanding the working principle of water spray retorts is essential for food manufacturers looking to optimize their sterilization process. With faster heating, lower energy consumption, and precise control, water spray retorts are a valuable investment for sustainable and cost-effective food processing.

Looking for a high-efficiency water spray retort? Contact LONKIA Machinery today for expert solutions tailored to your production needs!